Installation Guide for PPR Pipes and Fittings

Check The PPR Pipe Before Installation

Before installing PPR pipes, you should carefully check the relevant quality assurance certificates of the products, check whether there are air bubbles, cracks and grooves on the appearance of the pipes, whether the pipe ends are broken, whether the appearance of the whole pipe is smooth, and the color is uniform.

Check that the size or number of the pipe complies with the standard. Because the wall thickness and out-of-roundness of the pipe are important factors to ensure that the pipe installation is watertight. The thinning of the pipe wall thickness will affect the pressure rating of the pipe, and cracking is prone to occur during use.

If the size deviation of the pipe material is large, it will easily lead to insufficient sealing of the pipe connection and low connection strength, resulting in water leakage.

PPR Pipe Connection

PPR water supply pipes mainly use hot-melt connections.

If there is no good hot-melt connection operation method, even if a good pipe material is selected, it is still difficult to ensure the installation quality of the pipe.

If you want to ensure the quality of the connection, you must first choose a good hot-melt tool. The heating time and heating temperature of the heat welding machine should be strictly implemented according to the operating procedures.

Before the pipe is welded, the surface of the pipe and the joint should be carefully cleaned, and the oil, impurities, and burrs on the surface of the pipe should be removed.

It should be noted that the length of the pipe inserted into the pipe fitting should be appropriate, and a uniform flange should be formed at the pipe joint after connection.

If it is uneven, or even has a gap on one side, it means that the welding is not ideal, and it is difficult to ensure that the joint does not leak, and it should be reconnected in time.

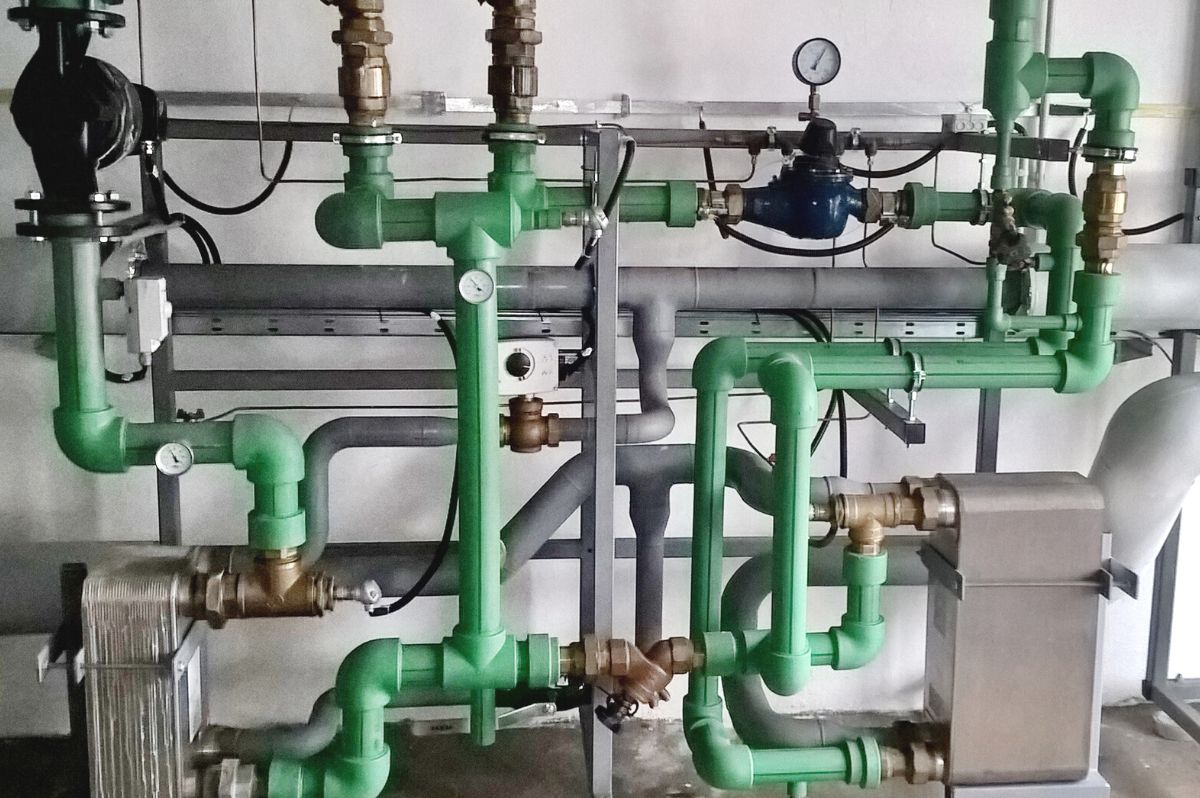

PPR Pipe Installing

The PPR pipe adopts the hot-melt connection form, and the connection between the pipe material and the pipe fittings can only be used once. Therefore, when the water supply pipe is installed in the wall, it must be accurately implemented according to the design requirements and the specific conditions of the construction site.

If the pipeline is laid underground, care should be taken to minimize the number of joints in the buried part. After the pipeline is installed, the location of the pipeline should be indicated with colored paint on the wall or on the ground to avoid damage to the pipeline during secondary decoration.

At the same time, it is also very important for the installation of PPR pipes to set up pipe supports by the specifications.

Treatment of Pipeline Linear Expansion

Since the expansion coefficient of the PPR pipe is much larger than that of the metal pipe, the expansion and contraction length of the pipe is also large, so it should be paid attention to in the pipe installation.

For the pipes laid in the wall, after the installation is completed, the space around the pipes in the pipe groove should be tightly sealed with fine cement mortar, relying on the friction resistance between the pipe and the cement mortar and the unique creep properties of plastic pipes to make the axial expansion and contraction This translates into radial variation, thereby eliminating linear deformation forces.

Therefore, the pipes laid in the wall can not consider linear expansion. For pipelines installed outside, when the straight-line distance is long, the free arm compensation method should be used to solve the thermal expansion deformation of the pipeline, that is, to give the pipeline space and room for free expansion and contraction.

Generally, pipelines are arranged in L and Z shapes, and appropriate fixed and movable supports are configured to achieve compensation. The length of the free arm should be checked by calculation, and the influence of seasons on the expansion and contraction length of pipelines should be considered.

Pipe Anti-Ultraviolet Treatment

Since PPR pipes are prone to aging due to long-term exposure to ultraviolet light, during construction design, consideration should be given to placing the pipes in places such as patios, shaded surfaces, and pipe wells with less sunlight.

If it must be installed in a place with strong sunlight, measures such as wrapping anti-ultraviolet film or outsourcing aluminum foil should be used to avoid premature aging of the pipeline.

Similarly, when the pipeline is stored in the open air before installation, shelter measures should also be taken.

PPR Pipe Hydrostatic Test

To ensure the quality of the hot-melt connection of the pipeline, a hydraulic test must be carried out on the pipeline after 24 hours of hot-melt connection or before concealment.

During the pressure test, firstly fill the pipeline with water, discharge the air in the pipeline, and then slowly increase the water pressure to the specified test pressure with a pressure pump, and the pressure increase time shall not be less than 10 minutes.

The test pressure of the cold water pipe should be 1.5 times the working pressure of the system, but not less than 1.0 MPa; the hot water pipe should be 2.0 times the working pressure of the system, but not less than 1.5 MPa.

Stabilize the pressure for 1 hour, check whether there is any leakage at each connection port and whether the pressure drop exceeds 0.05 MPa. If the pressure drop exceeds the allowable value, the cause must be found, and the pressure test should be performed again to ensure the quality of the pipe interface.

NBQXHY is a Chinese manufacturer specializing in plastic pipes, fittings, and valves. If you are interested in our PPR valves, pipes and fittings, welcome to contact our experts.

Alternatively, you can also click here to visit our page dedicated to PPR pipe fittings. Discover and learn more about our extensive range of PPR pipe fittings here.